Why Choose a Professional Metal Sculpture Manufacturer?

Bringing a monumental artistic vision to life involves much more than just welding metal together. You might be asking: “Will this structure withstand high winds?” “How do I ship a 20-foot sculpture overseas?” or “Will the finish fade after one summer?” These are real concerns. As a dedicated metal sculpture manufacturer, Artvision Sculpture Group bridges the gap between artistic concept and engineering reality. Unlike general industrial fabricators who treat every job like structural beams, we understand that every curve and surface finish is critical to the artwork’s soul.

Solving Key Challenges in Large Scale Metal Art

Executing custom metal sculpture fabrication requires a specialized skillset that goes beyond standard construction. We tackle the complex issues that derail projects handled by inexperienced teams:

- Scale & Engineering: We calculate wind loads and internal structures for monumental urban sculpture manufacturing, ensuring safety without compromising the design.

- Precision & Aesthetics: Industrial shops often ignore surface quality. We obsess over seamless welds and mirror polishing.

- Logistics: Moving a massive piece requires specialized crating and shipping knowledge that only an experienced outdoor metal sculpture supplier possesses.

Partnering with Experts vs. General Fabricators

Many clients unknowingly hire brokers or general steel shops, leading to miscommunication and inflated costs. Working directly with us ensures your artistic vision isn’t lost in translation. We protect the structural integrity and long-term performance of your investment.

The Artvision Difference:

| Feature | Professional Sculpture Manufacturer (Us) | General Fabricator / Broker |

|---|---|---|

| Focus | Artistic fidelity & fine detailing | Speed & industrial utility |

| Engineering | Hidden internal structures for art | Bulky, visible supports |

| Communication | Direct access to the technical team | Filtered through middlemen |

| Finish Quality | Museum-grade (Mirror, Patina, Paint) | Industrial standard (often rough) |

| Cost | Factory-direct pricing | Markups added at every step |

By choosing a specialized partner, you ensure that your project is built by craftsmen who respect the art, using materials designed to last for generations.

Our Comprehensive Metal Sculpture Manufacturing Process

As a dedicated metal sculpture manufacturer, we have refined a turnkey workflow that bridges the gap between artistic concepts and industrial reality. We don’t just fabricate; we engineer art to withstand the elements while maintaining the artist’s original intent. Our process ensures that every curve, weld, and finish meets the highest standards of custom metal sculpture fabrication.

Step 1: Consultation and Design Optimization

Every project begins with a deep dive into your vision. We utilize advanced 3D modeled metal sculpture technology, including 3D scanning and CAD modeling, to convert rough sketches into precise digital blueprints. This stage includes critical structural engineering calculations to ensure stability for large-scale installations. We optimize the 3D model to fix any potential fabrication issues before metal is ever cut.

Step 2: Material Selection and Prototyping

Choosing the right material is vital for longevity. We guide you through selecting premium options, whether it is marine-grade 316 stainless steel for coastal areas or specific alloys for casting. For complex shapes, we often produce a 3D-printed scale prototype, allowing you to visualize the final form and proportions physically.

Step 3: Precision Fabrication

Our production floor combines modern technology with old-world artistry. We employ CNC fabricated metal art techniques for exact cutting, followed by traditional hand-forging and welding. For cast pieces, we utilize the traditional lost-wax method, ensuring that understanding bronze worth and lasting value translates into a timeless final piece. This hybrid approach allows us to achieve seamless joints and fluid lines that machines alone cannot replicate.

Step 4: Professional Surface Finishing

The finish defines the sculpture’s character. Our craftsmen are experts in:

- Mirror Polishing: Creating a flawless, reflective surface typical of modern mirror polished stainless sculpture.

- Patina & Painting: Applying custom chemical patinas for bronze or automotive-grade spray painting for vibrant colors.

- Matte & Brushed: Providing a subtle, contemporary industrial look.

Step 5: Quality Control and Pre-Shipment Testing

We believe in “measure twice, cut once.” Before anything leaves our factory, we perform a full trial assembly. This pre-installation test verifies that all structural components fit perfectly and that the surface finish is consistent. We invite clients to inspect the work via video call or in person to approve the details.

Step 6: Secure Packaging, Global Shipping, and On-Site Installation

Logistics are often the hardest part of the job, but we handle it all. We provide overseas sculpture shipping and assembly, using custom-built steel crates with soft foam protection to prevent transit damage. Once the piece arrives, our experienced installation team—the same craftsmen who built the sculpture—can travel to your site to handle the final erection and welding, ensuring the artwork is installed safely and correctly.

Premium Materials Used by Our Metal Sculpture Manufacturer Team

As a dedicated metal sculpture manufacturer, we understand that the longevity of an artwork depends entirely on the quality of the raw materials. We don’t cut corners. Whether you are commissioning a centerpiece for a corporate lobby in New York or a public park installation in Florida, we select alloys that balance artistic vision with structural reality. We primarily work with high-grade metals that ensure your investment withstands the elements.

Stainless Steel (304/316 Grade)

For modern, sleek designs, we operate as a specialized stainless steel sculpture factory. We use 304-grade steel for standard indoor environments and 316-grade (marine-grade) for outdoor projects.

- Durability: 316 stainless steel contains molybdenum, which drastically increases corrosion resistance against salt and moisture.

- Finishes: We offer mirror polished stainless sculpture surfaces, matte, brushed, or painted finishes.

- Application: Ideal for contemporary abstract forms and large scale metal art.

Corten Steel (Weathering Steel)

Corten steel public art has become incredibly popular for landscapes requiring an organic, industrial aesthetic.

- Characteristics: This material develops a stable, rust-like appearance after exposure to weather. This “patina” acts as a protective layer that prevents further corrosion.

- Aesthetic: Delivers warm, earthy tones that blend seamlessly with gardens and parks.

- Maintenance: Extremely low maintenance; it heals itself if scratched.

Bronze and Brass

We combine modern engineering with traditional artistry at our bronze sculpture foundry. Using the lost wax casting bronze sculpture method, we create pieces rich in detail and history.

- Process: We cast molten bronze (typically a copper-tin alloy) into precise molds to capture intricate textures.

- Longevity: Bronze is timeless and increases in value over time. Placing a high-quality bronze statue outside ensures a lasting impression that can survive for centuries with minimal care.

- Finish: Available in various chemical patinas (brown, green, black) or polished gold hues.

Copper and Aluminum

For specific architectural needs, we utilize copper and aluminum.

- Aluminum: Lightweight and strong, making it perfect for hanging sculptures or massive installations where weight load is a concern. It holds paint and powder coating exceptionally well.

- Copper: Soft and malleable, used for hand-forged relief work. It naturally oxidizes to a distinct green verdigris over time.

Material Comparison Guide

Choosing the right material is critical for your project’s success. Here is a quick breakdown of how our materials compare:

| Material | Durability (Outdoor) | Maintenance Level | Aesthetic Outcome | Ideal Use Case |

|---|---|---|---|---|

| 316 Stainless Steel | Excellent (Marine Grade) | Low (Periodic cleaning) | Modern, Reflective, Sleek | Coastal areas, urban plazas, luxury hotels |

| Corten Steel | Very High | Very Low (Self-sealing) | Rustic, Industrial, Earthy | Public parks, gardens, desert landscapes |

| Bronze | Legendary (Centuries) | Medium (Waxing needed) | Classic, Detailed, Prestigious | Memorials, figurative statues, museums |

| Aluminum | High (If coated) | Low | Painted, Vibrant, Lightweight | Suspended art, colorful abstract pieces |

| Copper | High | Medium | Warm, Evolves (Verdigris) | Decorative cladding, roof features |

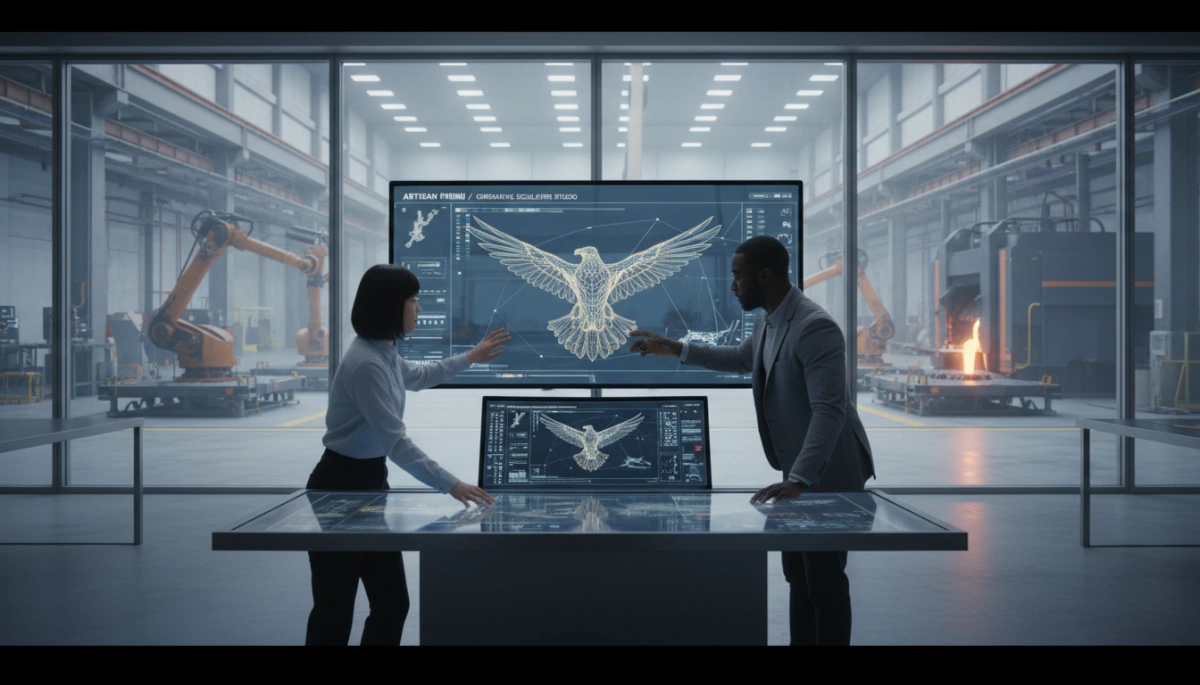

Advanced Technology and Craftsmanship

As a premier metal sculpture manufacturer, we bridge the gap between industrial precision and fine art. We don’t just rely on traditional methods; we integrate cutting-edge technology to ensure every curve and angle matches your original vision. This combination of digital accuracy and manual skill allows us to tackle complex geometries that standard fabricators simply cannot handle.

3D Modeling and Digital Optimization

Before any metal is cut, we utilize advanced 3D modeled metal sculpture techniques to perfect the design. Our engineering team creates detailed CAD models and performs structural calculations to guarantee stability.

- 3D Scanning & Printing: We scan original maquettes and print 3D models to verify proportions.

- Digital Enlargement: This ensures the final large-scale piece retains the exact details of the smaller model without distortion.

- Structural Analysis: We simulate wind loads and stress points to ensure safety for public installations.

Precision CNC Fabrication and Robotic Welding

To achieve exact specifications, we employ CNC fabricated metal art processes. Our workshop is equipped with CNC laser cutters that slice through stainless steel and corten plate with sub-millimeter accuracy. For internal structures and primary joins, we utilize robotic welding to ensure consistent, high-strength bonds that withstand the elements.

Blending Hand-Forging with Modern Tech

While machines provide the framework, the soul of the sculpture comes from our artisans. We blend these digital workflows with traditional hand-forging and lost-wax casting. After the CNC machines define the shape, our master craftsmen hammer, grind, and polish the surface by hand. You can see how we execute complex metal artworks designed by Huang Yulong where digital design meets manual artistry.

Accuracy in Large-Scale Projects

Technology is crucial for maintaining accuracy in monumental works. For massive installations, even a fraction of an inch off at the base can lead to major alignment issues at the top. Our digital measurements ensure that every section fits together perfectly during on-site assembly. This level of precision is especially critical for large bronze sculptures and architectural centerpieces that demand both aesthetic beauty and structural permanence.

Global Delivery and Professional Installation Services

Getting a monumental artwork from our factory floor to your site is a critical phase where many general fabricators fall short. As a dedicated metal sculpture manufacturer, we provide a seamless “door-to-door” experience, managing every logistical detail so you don’t have to. We understand that for our US clients, the reliability of overseas sculpture shipping and assembly is just as important as the fabrication quality.

Factory-Direct Shipping & Protection

We do not leave anything to chance when transporting large-scale art. Every project undergoes a rigorous packaging regime designed specifically to withstand the rigors of international ocean freight and inland trucking.

- Custom Packaging: We utilize soft foam wrapping combined with sturdy wooden crates and custom-welded internal iron frames. This prevents any movement or surface scratching during transit.

- Full Insurance: All shipments are covered by comprehensive insurance, providing you with complete financial protection from the moment the piece leaves our facility until it arrives at your project site.

- Logistics Management: We handle the complexities of customs clearance and coordinate final delivery to your specific location.

Expert On-Site Installation

Our commitment extends beyond the workshop. We offer professional metal sculpture installation services where our own skilled craftsmen travel globally to assemble and secure the piece. This approach offers significant advantages over hiring unconnected local contractors.

- Continuity of Craft: The same artisans who built the sculpture perform the final installation. They understand the internal engineering, weight distribution, and specific assembly points better than anyone else.

- Precision Assembly: Whether we are installing a contemporary stainless steel landmark or a traditional work requiring the delicate handling described in how bronze sculptures are made, our team ensures the final setup matches the design intent perfectly.

- Seamless Execution: Our experienced in-house teams work efficiently to ensure structural stability and aesthetic perfection, minimizing disruption to your venue.

Notable Projects and Portfolio Highlights

As a dedicated metal sculpture manufacturer, our track record speaks for itself. With over 12 years of industry experience, we have successfully executed more than 100 large-scale projects across the globe. Our portfolio demonstrates our ability to bridge the gap between artistic concept and engineering reality, handling everything from monumental urban sculpture installations to intricate private commissions.

We pride ourselves on diversity, working with various metals and finishes to suit specific environments. Below are examples of the types of landmark projects we deliver:

- Monumental Public Landmarks: We specialize in engineering and fabricating massive outdoor structures that define cityscapes. Our team regularly produces large scale metal art exceeding 7 meters in height. These projects often utilize 316-grade stainless steel with internal structural reinforcement to withstand high wind loads and public interaction.

- Abstract Corporate Commissions: Many of our clients require sophisticated centerpieces for hotel lobbies or office plazas. We frequently produce abstract bronze figure sculptures that combine traditional lost-wax casting with modern patinas, offering a timeless aesthetic that enhances professional environments.

- Contemporary Colorful Installations: Moving beyond standard metallic finishes, we create vibrant visual statements using automotive-grade spray painting. A prime example of this capability is our work on spray painting stainless steel tower sculptures, which brings a dynamic pop of color to parks and commercial districts while maintaining corrosion resistance.

- Mirror-Polished Garden Art: For high-end residential and gallery settings, we fabricate mirror polished stainless sculptures. These pieces require flawless hand-forging and polishing to create a seamless, liquid-like surface that reflects the surrounding landscape, blending art with nature.

- Custom Weathering Steel Projects: We also work extensively with Corten steel for public parks requiring a rustic, industrial look. These sculptures are designed to develop a stable, protective rust layer over time, minimizing maintenance while delivering a striking organic appearance.

Every project we undertake, whether a massive outdoor metal sculpture or a delicate gallery piece, is backed by our commitment to precision engineering and artistic integrity.

What Sets Artvision Sculpture Group Apart

Choosing the right partner is critical when bringing a complex artistic vision to life. As a dedicated metal sculpture manufacturer, Artvision Sculpture Group bridges the gap between industrial capability and fine art craftsmanship. We do not just fabricate metal; we engineer longevity and aesthetic precision into every curve and weld.

Here is why artists, architects, and developers trust us with their custom metal sculpture fabrication:

- Proven Track Record: With over 12 years of focused expertise, we have successfully completed more than 100 large-scale projects worldwide. Our experience covers a wide range of applications, ensuring we understand the specific engineering requirements for public plazas, hotels, and private gardens.

- Unique “One-Piece” Focus: Unlike factories that demand high volume, our minimum order quantity is just one piece. We treat every commission as a unique artwork, dedicating the same level of detail to a single stainless steel sculpture as we do to monumental urban projects.

- Intellectual Property Protection: We understand the value of your design. We offer strict Non-Disclosure Agreements (NDAs) to ensure your creative concepts remain secure and exclusive throughout the production process.

- Transparent Project Management: You receive dedicated, one-on-one service. From the initial 3D modeled metal sculpture review to the final logistics, our team provides clear updates and structural calculations to keep your project on track.

- Comprehensive Warranty: Our commitment extends beyond delivery. We provide a solid warranty and long-term post-installation support, giving you confidence that your investment will withstand the elements for decades.

Frequently Asked Questions About Metal Sculpture Manufacturing

What is the typical lead time for custom metal sculptures?

Timeframes depend heavily on the complexity and scale of the project. For most standard custom metal sculpture fabrication, the process takes approximately 1 to 2 months. However, for monumental urban projects or large-scale landmarks exceeding 7 meters in height, production generally requires 3 to 4 months. This schedule allows us to maintain high standards during the 3D modeling, structural calculation, and hand-forging stages.

How do you ensure outdoor sculptures withstand harsh weather?

Durability is our priority for any outdoor metal sculpture supplier. We primarily use 304 and 316 grade stainless steel for their superior corrosion resistance. For coastal or high-humidity environments, we recommend 316 marine-grade steel to prevent rusting. Additionally, our engineering team performs structural calculations to ensure the internal framework can withstand local wind loads and environmental stress, delivering a truly weatherproof metal garden sculpture or public installation.

Can you assist with design if I only have a rough concept?

Absolutely. We specialize in bridging the gap between artistic vision and industrial production. If you have a sketch, a photo, or just an idea, our design team uses advanced 3D modeled metal sculpture software to create detailed digital renderings. We optimize these models for structural integrity and manufacturability before any metal is cut, ensuring the final result matches your vision perfectly.

What are the shipping and installation costs?

Shipping and installation are calculated based on the sculpture’s dimensions, destination, and site conditions. We provide a “Quick Quote” service to give you a clear estimate early in the process. For clients considering different materials, it is helpful to understand the cost of bronze before you invest compared to stainless steel, as weight and material value significantly impact the final budget. We handle all logistics, including custom crating and overseas sculpture shipping and assembly.

Do you provide maintenance guidelines or repair services?

Yes, we view our relationship with clients as a long-term partnership. Upon delivery, we provide detailed maintenance instructions tailored to the specific finish of your artwork, whether it is mirror-polished stainless steel or a patinated bronze. As a dedicated metal sculpture manufacturer, we also offer long-term consultation and can advise on restoration or repairs should your sculpture ever sustain damage.

Add a Comment