Abrication & Engineering

Precision, craftsmanship, and technology — the foundation of every Artvision sculpture.

Craftsmanship Meets Modern Engineering

At Artvision Sculpture, we combine traditional artistry with modern engineering to produce high-quality metal sculptures that meet international standards.

Our workshop is equipped with advanced machinery, professional tooling, and specialized production areas for metal forming, welding, casting, and polishing, ensuring that every stage of fabrication is handled with precision and care.

From small-scale artworks to monumental public installations, we bring together creative vision and technical mastery to achieve outstanding results for clients worldwide.

Our Workshop & Equipment

Our fabrication facility is designed for flexibility, safety, and precision.

We maintain a full range of production equipment to support various metalworking processes, including:

CNC cutting and laser shaping systems

TIG and MIG welding stations for stainless steel and bronze

Precision casting furnaces and temperature-controlled kilns

Polishing and surface finishing rooms (mirror, matte, or patina)

Internal frame assembly and structural testing areas

All equipment and procedures comply with international production and safety standards, ensuring consistent quality and reliable performance throughout each project.

Experienced Craftsmen & Skilled Teams

Behind every great sculpture is a great team.

Our workshop is home to a group of experienced master craftsmen, many of whom have over 15–20 years of hands-on experience in sculpture fabrication.

Their deep understanding of metal behavior — how it bends, reflects, and endures — allows them to execute even the most complex forms with remarkable accuracy and artistry.

Each sculpture undergoes multiple quality checks and internal reviews to ensure it meets both artistic intent and engineering integrity.

Two Core Fabrication Techniques

At Artvision, we specialize in two main fabrication methods, each carefully selected based on the nature and requirements of the sculpture.

Lost-Wax Casting (Traditional Craft)

The lost-wax casting process has been used for centuries to create detailed and durable bronze sculptures.

It allows for highly refined surface textures and intricate artistic details, making it ideal for figurative and classical works.

Our casting team follows each step — from wax modeling, mold making, and pouring molten metal, to chasing, welding, and patination — with meticulous precision.

This traditional method preserves the depth, warmth, and individuality of the sculpted form.

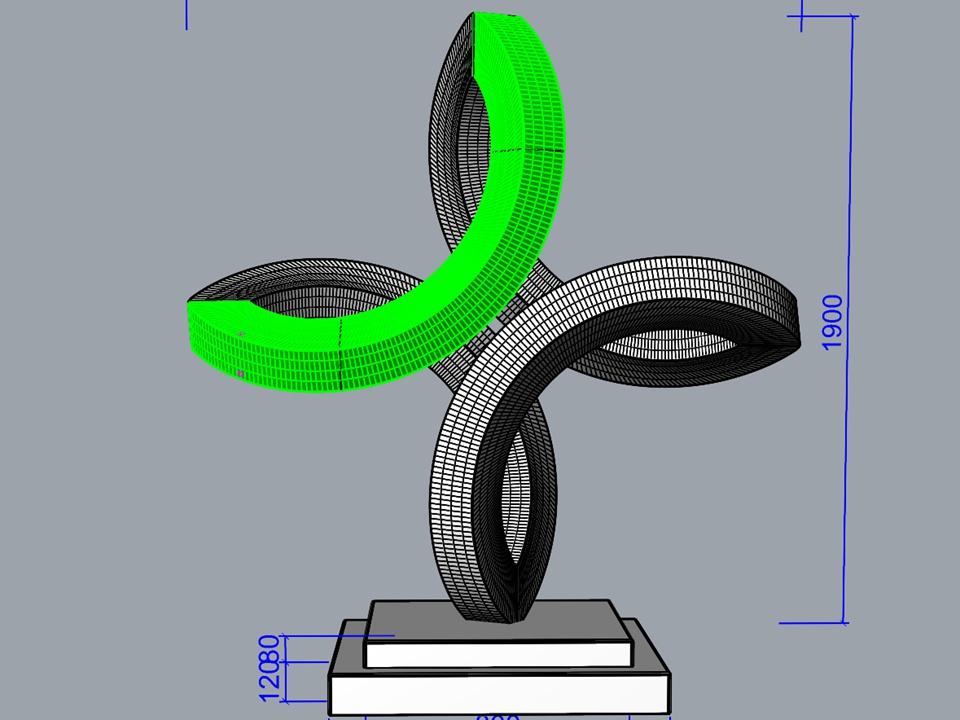

Hand Forging & Fabrication (Modern Craft)

For contemporary designs and large-scale outdoor installations, we employ hand forging and modern fabrication techniques.

Using stainless steel, copper, brass, or corten-steel materials, our craftsmen shape and assemble the sculpture through precision forming, TIG welding, and surface treatment.

This process allows for lightweight yet strong structures, seamless finishes, and large smooth surfaces often seen in modern public or architectural artworks.

Forged works demonstrate clarity of form, structural integrity, and a refined aesthetic — representing the modern language of sculpture.

Engineering Support & Structural Design

Our engineering department works closely with the design team to ensure each sculpture is not only visually striking but also safe and durable.

We provide complete structural drawings, material strength analysis, and installation planning for every project.

Internal frameworks are engineered using 304 stainless steel, 316L stainless steel or carbon steel, depending on the sculpture’s scale and environmental conditions.

Before fabrication, all designs undergo a full technical review, balancing artistry with stability and longevity.

Quality & Project Evaluation

Quality is the core of our work.

Before each sculpture leaves our factory, it passes through multiple inspection stages, including:

Dimensional and surface accuracy checks

Structural welding tests

Surface treatment and color consistency evaluations

Packing and installation readiness verification

We also review past project data and feedback to continually improve efficiency and craftsmanship, ensuring every new project benefits from our accumulated experience.

Our Commitment

With decades of experience in both lost-wax casting and hand-forged metal fabrication, Artvision Sculpture stands for excellence in every detail.

We are proud to unite artistic craftsmanship, engineering precision, and advanced technology — creating sculptures that endure through time and inspire generations.

We welcome collaborations from artists, architects, and developers worldwide — bringing creative visions to life through fine craftsmanship and engineering expertise.